Residential License # 890459

Commercial License # 3667

Call Us Today!

Residential License # 890459

Commercial License # 3667

Call Us Today!

TurnKey Welders in New Orleans is the top choice for excellent window welding services. Our expert team guarantees every job is done perfectly, meeting all kinds of needs—whether it’s making your home look better and work smoother or fitting out business properties to stand up to tough demands.

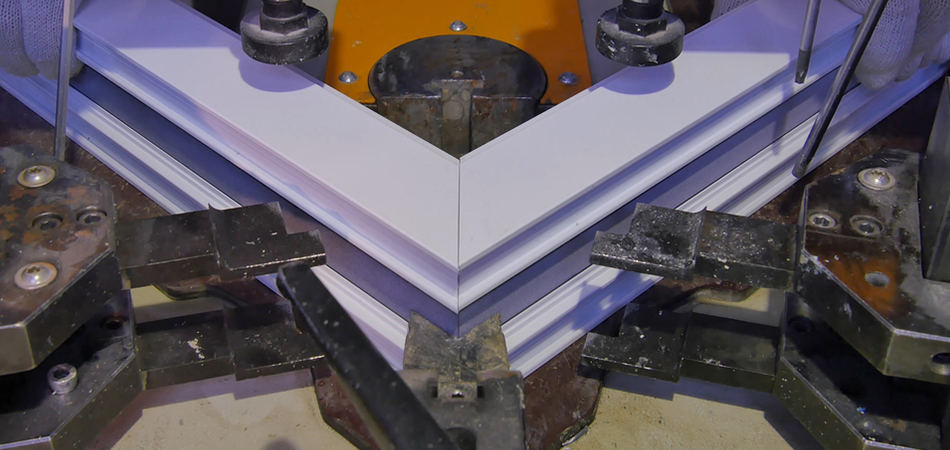

We know windows are more than just holes in walls; they’re key for both the look and strength of your building. We offer top-notch welding services to make sure your windows are not only installed firmly but also look better. We’re committed to quality, using the best materials and latest methods, ensuring your windows last long.

Making our customers happy is our top priority. We listen to what you need and want, offering custom welding solutions that fit just right. Whether it’s installing new windows or fixing the old ones, trust us to deliver quality, efficient, and good-looking welding work.

Choosing us gives your property both durability and style. Our expert window welding services guarantee your windows will work perfectly and enhance your property’s value. We’ll make your home or business in New Orleans stand out with great-looking welded windows. Rely on TurnKey Welders for top-notch window welding where quality craftsmanship is key.

Mobile welding brings the workshop to you, eliminating the need for transporting bulky materials. This service is all about convenience and flexibility, allowing welding tasks to be completed right where the client needs them.

It’s perfect for emergency repairs or immediate on-site fabrications. Projects ranging from fixing a broken gate to constructing a new metal structure are ideal for mobile welding.

Our team stands ready 24/7 for urgent repair needs, ensuring help is always available when unexpected damages occur.

Our team stands ready 24/7 for urgent repair needs, ensuring help is always available when unexpected damages occur.

We handle a wide range of repair work, from minor fixes to extensive structural repairs. Our expertise spans various metals and materials, offering comprehensive solutions for any repair scenario.

Restoring antique metal items or historic structures requires a professional touch. Welding can revive old or damaged metal, restoring its original form and function.

It’s crucial for preserving both the value and integrity of the piece, whether it’s an ornate fence or a century-old building component.

From creating industrial components to crafting unique home decor, the scope of fabrication services is vast. The use of advanced welding technology ensures that each piece is not only high-quality but also durable. A collaborative approach between welders and clients guarantees that the final product aligns perfectly with expectations, blending functionality with aesthetic appeal.

Welders can transform metal frameworks to meet new specifications. This process often involves cutting, shaping, and joining metal in precise ways. It allows for the extension or reduction of existing structures.

Welding offers the flexibility to customize and strengthen window frames. Skilled technicians can adapt metal pieces for enhanced performance. They ensure each modification suits the client’s needs perfectly.

Restoring historic windows requires a delicate touch. Specialized welding techniques preserve original designs while reinforcing structural integrity. Craftsmen face challenges such as reversing years of corrosion without losing detail.

Successful projects showcase the potential of welding in restoration. These efforts breathe new life into aged metals, maintaining their historical value. Each project serves as a testament to the welder’s skill in balancing preservation with improvement.

Beyond repairs, our window welding services include creating new components from scratch. This process involves designing, cutting, and assembling metals to form complete structures. Fabrication allows for the creation of bespoke window designs that fit specific architectural styles or personal preferences.

Custom fabrications offer unique solutions for both residential and commercial spaces. They demonstrate the versatility of welding in crafting distinctive, durable window installations.

We shine when it comes to emergency structural repairs. Our team swiftly addresses damages that could compromise the integrity of buildings or structures. Businesses benefit greatly from this rapid response. It minimizes potential hazards and operational disruptions. Homeowners also find solace in quick fixes that prevent further damage to their property.

Another key area is equipment repair. We mend broken machinery on-site. This service is invaluable for industries relying heavily on continuous operation. We fix manufacturing equipment, agricultural machinery, and more without the need for transportation to a separate facility. This significantly cuts down on downtime and loss of productivity.

Mobile welders also undertake vehicle modifications and repairs. We customize cars, trucks, and even boats to meet specific needs or restore them after damage. This flexibility allows for personalized adjustments directly at the owner’s location. It saves time and ensures vehicles are modified with precision.

Safety is paramount during mobile welding operations. We adhere to strict safety protocols to protect ourselves and our clients’ properties. We use protective gear and follow best practices to prevent accidents. Quality control measures ensure repairs meet industry standards, ensuring durability and reliability of the work done.

Mobile welding brings essential services directly to construction sites. These include structural steel welding, onsite repairs, and custom fabrications. Such services are crucial for the safety and durability of buildings and infrastructure. Our welders have a track record of contributing to construction projects with their expertise. Our work ensures that structures stand the test of time.

In the automotive sector, mobile welding plays a pivotal role in repairing collision damage and facilitating custom vehicle modifications. The precision in these tasks is vital for maintaining a vehicle’s integrity and performance.

We can handle a broad spectrum of vehicles, from cherished classic cars to sleek modern models. This versatility showcases their ability to meet specific client requirements while upholding high standards.

The manufacturing industry relies on mobile welding for onsite repairs, equipment modifications, and prototype development. These services are key to keeping production lines moving without significant downtime.

Timely and efficient support from welders helps manufacturers adhere to tight schedules. Moreover, their adaptability allows them to cater to the varied needs of manufacturing clients, proving indispensable in this fast-paced environment.

Materials significantly impact the total cost. Prices vary based on metal types like steel, aluminum, or specialty alloys. Clients must consider the price of consumables like gas and filler material. Steel often costs less than aluminum. However, specialty alloys can double the price. Consumables add to the expense but are essential for quality work.

Labor accounts for a large portion of expenses. Skilled welders command higher rates due to their expertise. The duration of the project also affects labor costs. Experienced welders ensure efficiency and quality. Longer projects naturally incur higher labor charges. Clients should discuss time estimates upfront to manage expectations.

Complex tasks require more time and skill, increasing costs. Accessibility issues or intricate designs can complicate welding jobs. Challenged projects demand advanced skills, leading to higher rates. Simple repairs are usually more affordable than complex fabrications.

Mobile welding offers unmatched convenience and flexibility. It saves clients time by bringing services directly to them. This approach solves problems on-site without the need for transport.

The convenience of mobile welding often outweighs its cost. On-the-spot problem solving minimizes downtime for businesses, proving invaluable. Clients can estimate their project’s cost by considering these factors and consulting with professionals. A detailed discussion helps in creating an accurate budget plan.

To start a mobile welding project in New Orleans, the first step is reaching out to us. Clients can contact us via phone or email. They should provide details about their welding needs. Upon receiving an inquiry, we will schedule a consultation. This allows us to understand the project’s scope better.

We conduct a thorough site assessment. We visited the location to evaluate the work needed. This step is crucial for accurate quoting and planning. Our team considers factors like location accessibility and material requirements. Our local expertise ensures we are familiar with New Orleans’ unique architectural styles.

Once the quote is accepted, we begin the welding work. We bring all necessary equipment to the client’s location. Our team works efficiently to complete projects on time. We ensure every weld meets high standards of quality and durability. Clients can expect regular updates throughout the project.

Clients unsure about their specific needs can seek personalized advice from TurnKey Welders. Our extensive experience in New Orleans’ industrial landscape makes them invaluable advisors. We can recommend solutions tailored to each client’s situation.

When it comes to ensuring the durability and efficiency of your windows in New Orleans, TurnKey Windows is your trusted partner for professional window welding services.

Our skilled technicians specialize in window welding, a process that involves fusing or repairing damaged window frames and components using advanced techniques and materials. Whether you’re dealing with broken frames, sealant issues, or other structural issues, we have the expertise to restore your windows to optimal condition.

We prioritize quality and customer satisfaction. We use industry-leading practices and premium materials to deliver lasting results that enhance the performance and appearance of your windows.

Whether you’re a homeowner, property manager, or business owner in New Orleans, you can rely on TurnKey Windows for all your window welding needs. Contact us today to learn more about our services and schedule a consultation with our experienced team.

The specialized mobile welding service I recently used surpassed my expectations. They arrived on time with all the necessary equipment and completed the pipe welding job flawlessly. I’m incredibly pleased.

I was impressed with the expertise of the crew who worked on my iron railing. The attention to detail and precision in the welding work was exceptional. Highly recommended!

For my project, I required both non-shielded arc welding and shielded arc welding. TurnKey Welders demonstrated expertise in both techniques and delivered results that exceeded my expectations. I’m grateful for their professionalism!

I needed some welding work done on my fence and gate, and the service I received was top-notch. Their team was skilled and professional, and the results were outstanding. I’m very satisfied with the work done.

Window welding was something I wasn’t familiar with, but their team is knowledgeable and skilled. The quality of the work speaks for itself. I’m a happy customer.

The welding work done on my gate was superb. The welder’s attention to detail and commitment to ensuring a secure and sturdy gate was impressive. I’m extremely satisfied with the outcome.

I needed pipe welding services and was fortunate to find such a skilled welder. The welds are strong and clean, and I have confidence in the longevity of the work. I’ll definitely hire their services again.

The iron railing welding done by them was exceptional. The welds are not only secure but also seamlessly integrated into the design. It’s evident that the welder takes pride in their craft.