Residential License # 890459

Commercial License # 3667

Call Us Today!

Residential License # 890459

Commercial License # 3667

Call Us Today!

Quality pipe welding requires proper techniques, tools, and craftsmanship. At TurnKey Welders, we ensure our welds are durable, suitable for applications ranging from residential plumbing to industrial pipelines. Important factors like joint preparation, material compatibility, and controlled heat input lead to reliable results.

By emphasizing these techniques, we aim for strong, long-lasting performance in every project. Let’s talk about how we can support your next welding job—reach out to us today and put our expertise to work for you.

In the welding of pipes safely and of great reliability, the processes of quality assurance (QA) and quality control (QC) are fairly critical. They ensure that materials meet specifications, that welding processes are exact, and that systems function safely and efficiently. As New Orleans faces extreme challenges, with humidity and flooding, QA/QC will ensure the fabricated infrastructure is sustainable.

QA/QC ensures that every weld conforms to predetermined specifications to minimize the number of defects. Furthermore, non-destructive and destructive tests are performed early enough to identify the problems before their occurrence to avert cases, for example, minor ones such as leaking, from becoming expensive repairs.

Techniques like radiographic and ultrasonic testing expose internal flaws without affecting the weld, while destructive testing validates the strength of the material.

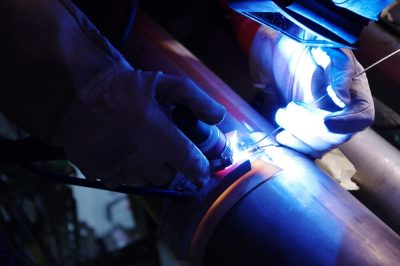

Welds have an essential role in the safety and longevity of piping systems. The first line of defense for the new residential plumbing or industrial pipelines is quality inspection. To ensure good system reliability and avoid delays, the correction of welds should be done under the right conditions, for example, with proper lighting.

Compliance with industry standards like ASME or AWS ensures the availability of consistent quality and reliable workmanship. A Comprehensive Quality Assurance Plan (QAP) guarantees that the tests and inspections will be accomplished at important milestones, where accountability of everybody in the welding work process is ensured.

Poor welding results in enormous financial loss. Sure, proper QA/QC results lower rework, schedule projects on time, and reduce maintenance costs in the long run.

To maintain quality in pipe welding, accurate inspection techniques are important. We focus on clear observation of the weld zone with over 30-degree observation angles, particularly when utilizing optical instruments. Adequate illumination is essential; we suggest more than 500 lux, preferably multispectral sources such as xenon at 4000-6000K for sharp details.

Inspectors need to be careful against misalignment dangers caused by warpage in big pipes, generally over 6 inches. The application of the 1951 USAF resolution test chart aids calibration of optics for reliable results.

An extensive knowledge of welding methods and materials is required to recognize such defects at their early stages. This fusion of technical procedures and attention to detail guarantees weld integrity.

Post-weld inspection is essential to guarantee the safety and reliability of pipe welds. We begin with a visual examination to inspect for apparent defects such as cracks and irregular beads, which enables the detection of problems at an early stage and saves time and resources.

For internal flaws, we employ non-destructive testing (NDT) techniques such as radiographic testing, which applies the use of X-rays to identify voids, and ultrasonic testing, which utilizes sound waves to identify subsurface defects.

Mechanical tests like tensile or bend tests determine weld strength and endurance. Standards differ in various industries, with greater requirements for high-pressure equipment. These tests validate quality and inform improvement for future welds.

With new tools, techniques, and training, pipe welding has developed into a highly efficient and very durable method in today’s industry. Such innovations increase the rate of production without compromising the quality of output, particularly in tough conditions such as construction.

Automation significantly improves accuracy in repetitive operations and intricate joints, like 5G and 6G welds. Robotic systems integrated ensure consistent welds, while rotating fixtures provide tighter tolerances. Automated FCAW systems provide controlled wire feeding and consistent heat, minimizing operator mistakes, especially with challenging materials like stainless steel.

Real-time equipment, like infrared sensors and ultrasonic inspection, is critical in detecting defects while welding. For visual examination, employing high-intensity lighting enables operators to observe weld seams. Sophisticated software can rapidly examine weld profiles, guaranteeing correct bevel angles and joint integrity.

Experienced welders play a key role in high-quality pipe welds. Advanced welding methods such as TIG welding demand precision, particularly in vertical and overhead positions. Certification programs guarantee welders are proficient in important skills and adhere to industry standards during inspection.

Temperature and humidity are two important factors that greatly influence weld quality. Cleaning surfaces during humid weather and preheating pipes in cold weather prevents defects. Post-weld cleaning, such as removing slag, also enhances the strength of the weld.

Quality in pipe welding begins with planning and proper equipment. Every step—pre-welding, during welding, and post-welding—leads to the reliability of the end product. Quality control is our foundation, building the foundation for our reliable service.

We give every project, from commercial builds to residential repairs, the same level of care and attention to detail. Trust is paramount in our relationships. For dependable, quality welding services supported by decades of experience, call us today at TurnKey Welders to work together on your next project.